High-speed cameras are helpful in response to a variety of issues, depending on the field in which they are used. They can be found, for example, in manufacturing companies, which use this type of camera to monitor their production line and ensure it is operating smoothly. Cameras of this quality detect any malfunctions immediately. So, in what kinds of areas can they be used? And how are they essential to productivity?

What is a high-speed camera?

A high-speed camera, or fast camera, is a camera that can capture hundreds or even thousands of images per second. The sequences it films can be analysed in great detail, with the precision required to identify a malfunction or a technical anomaly. The aim is to “stretch time” as far as possible and to spot what the human eye, or a more conventional camera, cannot. A second can be made to last 5 or 10 minutes!

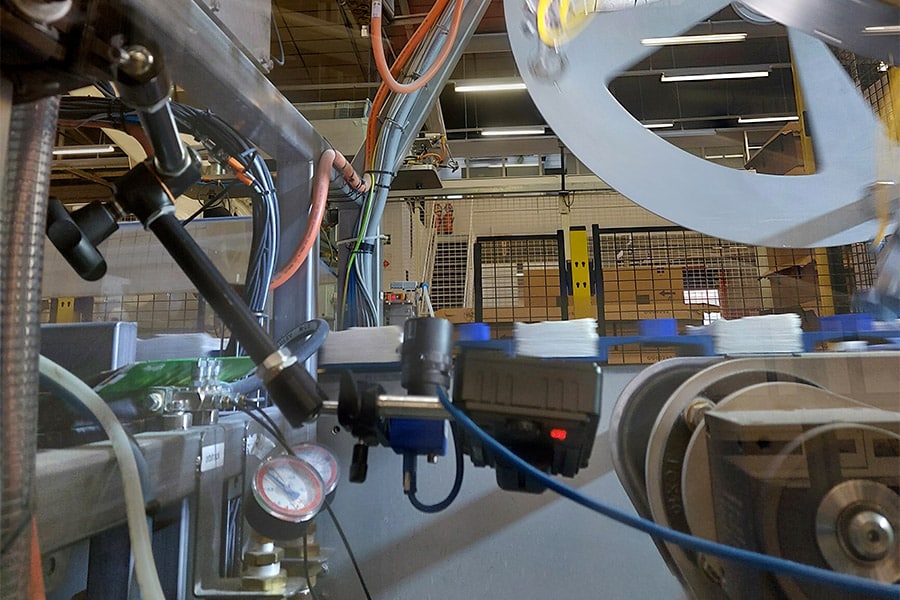

The high-speed Trouble Pad camera is an excellent example. Easy to install, this camera can monitor an entire production line and is a support tool for technical maintenance staff. In an industrial process context, it captures the images, enabling the operator to record footage, then access and analyse it to see where the fault occurs on the production line. Adjusting the scrolling speed makes it even easier to analyse the problem; this is what the Trouble Pad provides.

Where should high-speed cameras be used?

High-speed cameras have multiple possible applications and meet the needs of different industries. High performance spot recording on production or manufacturing lines is a real asset for fine-tuning machinery. It is used in pharmacology, cosmetology, the automotive industry, packaging, high-speed machinery manufacture, etc…

High-speed cameras… in the pharmaceutical industry

High-speed cameras are widely used in pharmacology, and are particularly useful. In the pharmaceutical industry, bottling, capping of vials and bottles, blistering of tablets, vials, etc. must be monitored with the most stringent checks.

Production lines in the pharmaceutical industry involve intensive output rates and require high safety levels. Manufacturing drugs, vaccines, injectable products (such as insulin) and ingestible products, etc. requires real speed with a rate of 200 to 500 strokes per minute, and sometimes even more depending on the manufacturing process in the company.

These speeds make it impossible to perform detailed analysis of the entire production chain and to identify any mechanical and industrial issues unassisted.

And yet, it is essential that these manufacturing operations are carried out in the best possible conditions and with full compliance.

Using a high-speed camera is particularly interesting and relevant for this type of application and in this field of activity.

In addition, it is also necessary to ensure that all the parts involved in the production lines are working perfectly. Bottles, blisters, syringes, dosage pens… must all comply with the customer’s specifications and must not be impacted by a technical glitch on the production line. The machinery, which sometimes performs several different operations, must be under constant supervision. High-speed cameras make that possible!

High-speed cameras… in the automobile industry

The high-speed camera is also used in the automotive sector, in crash tests.

Crash tests are an important process for guaranteeing vehicle, passenger and driver safety. Using one or more high-speed cameras is the best solution for ensuring the most accurate and reliable results, Crash tests are often used, including on expensive equipment and many cameras are essential to ensure that the tests are carried out properly. Several high-precision cameras are needed to monitor all angles and analyse all potential factors. For example, this system facilitates analysis of the driver dummy’s movement within the vehicle in the event of an accident, to record impacts, to analyse kinetic forces or any vehicle deformation…

High-speed cameras… in packaging

The high-speed camera also helps to visualise packaging lines and to ensure that everything is working perfectly. Whether it is bottling water, fruit juices, wines, champagnes, etc, corking bottles, packaging cheese, meat, vegetables, sweets, etc., making food cans, drinks cans or labelling, or all of the above!

All these applications can benefit from the use of high-speed cameras and fast image capture to analyse the finest details of the manufacturing process over the different stages, improving productivity. As production rates increase, settings need to be adjusted on production lines so that productivity levels do not suffer. The camera sees it all: an incorrectly placed cap, a missing lid, a can without a label, canning difficulties… Fast cameras are a real asset in the food industry!

High-speed cameras… for manufacturers

Of course, manufacturers of high-speed machinery are also concerned by this type of camera. Manufacturers can use high-speed cameras to adjust their machinery, perfect it, test it at high speed, fine-tune it and test all the features under the sharp eye of a high-speed camera. This enables process improvements, safe, well-running machinery and positive feedback from the end-users.

Proven usefulness at all times

The maintenance staff and technicians can therefore identify the fault, the anomaly, the technical issue that is slowing down production and holding the entire production line back, more quickly. Through the use of high-speed cameras, productivity is improved, time is saved and cost efficiency is achieved.

Be first to comment !